Zebra Print Labels: A Comprehensive Guide to Eye-Catching and Versatile Labeling Solutions

Step into the captivating world of Zebra Print Labels, where bold patterns and striking designs converge to create a visual symphony. These labels transcend mere functionality, becoming artistic expressions that elevate branding and communication strategies. From fashion to retail, healthcare to logistics, Zebra Print Labels are making a mark with their unique charm and versatility.

Zebra Print Labels are not just about aesthetics; they are a testament to the power of design in enhancing product recognition, streamlining operations, and capturing the attention of discerning consumers. In this comprehensive guide, we will delve into the intricacies of Zebra Print Labels, exploring their design elements, materials, production methods, customization options, and industry trends.

Zebra Print Label Definition and Use Cases

Zebra print labels are distinctive, eye-catching labels featuring a black and white striped pattern resembling the stripes of a zebra. They are highly versatile and find applications in a wide range of industries, including retail, manufacturing, healthcare, and logistics.

In retail, zebra print labels are often used to highlight special promotions, new arrivals, or discounted items. They can also be employed to create a unique and stylish aesthetic for a brand or product.

Use Cases

- Retail: Highlighting promotions, new arrivals, discounted items, and creating a unique brand aesthetic.

- Manufacturing: Identifying components, tracking inventory, and providing safety instructions.

- Healthcare: Labeling patient records, specimens, and medical devices.

- Logistics: Tracking packages, labeling shipping containers, and identifying hazardous materials.

Design Elements of Zebra Print Labels

Zebra print labels stand out from the crowd with their distinctive visual appeal. Their design elements, including color, pattern, and texture, play a crucial role in creating this captivating aesthetic.

The black and white stripes of zebra print are instantly recognizable. The contrast between these two colors creates a bold and eye-catching look that’s hard to miss. The width and spacing of the stripes can vary, creating different effects. Wider stripes give a more striking look, while narrower stripes create a more subtle and sophisticated appearance.

Texture

Zebra print labels often have a textured finish that adds depth and interest to the design. This texture can be created by embossing or debossing the material, or by using a special printing technique that creates a raised or recessed effect. The texture adds a tactile element to the label, making it more engaging to the touch.

Color Variations

While traditional zebra print features black and white stripes, modern labels offer a wider range of color combinations. Designers can choose from bold neon shades to more muted pastels, creating labels that suit a variety of tastes and styles. These color variations allow for greater customization and personalization.

Materials and Production Methods

Zebra print labels are typically made from a variety of materials, including paper, plastic, and vinyl. Each material has its own unique advantages and disadvantages, so it’s important to choose the right one for your specific needs.

Paper labels are the most common type of zebra print label. They’re inexpensive and easy to produce, making them a good choice for short-term applications. However, paper labels are not very durable and can be easily torn or damaged.

Plastic labels are more durable than paper labels and are resistant to water and tearing. They’re also more expensive than paper labels, but they can last for several years.

Vinyl labels are the most durable type of zebra print label. They’re resistant to water, tearing, and fading, making them a good choice for long-term applications. However, vinyl labels are also the most expensive type of label.

Production Methods

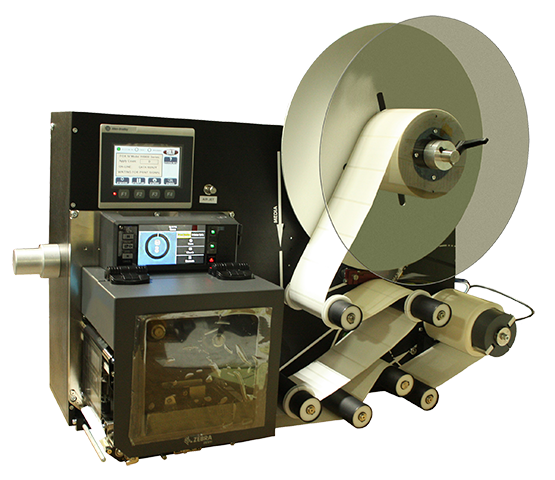

Zebra print labels can be produced using a variety of methods, including offset printing, digital printing, and flexography.

Offset printing is a traditional printing method that uses metal plates to transfer ink to paper. Offset printing produces high-quality labels with sharp images and text. However, offset printing is also a relatively expensive process.

Digital printing is a newer printing method that uses digital files to create images on paper. Digital printing is less expensive than offset printing, but it can produce lower-quality labels with less-sharp images and text.

Flexography is a printing method that uses flexible plates to transfer ink to paper. Flexography is a cost-effective method for producing large quantities of labels. However, flexography can produce lower-quality labels than offset printing or digital printing.

Latest Advancements

The latest advancements in label manufacturing include the use of new materials and printing technologies.

New materials, such as synthetic papers and films, are being developed to create labels that are more durable and resistant to water and tearing. New printing technologies, such as digital inkjet printing, are being developed to produce higher-quality labels with sharper images and text.

Customization and Applications

Zebra print labels offer a plethora of customization options to cater to the unique requirements of businesses. These labels can be tailored to reflect a company’s brand identity, enhance product recognition, and provide essential information to customers.

Customization Options

Businesses can personalize their zebra print labels in various ways, including:

– Color and pattern: The iconic black and white zebra stripes can be modified to incorporate different colors and patterns, creating a distinctive and eye-catching look.

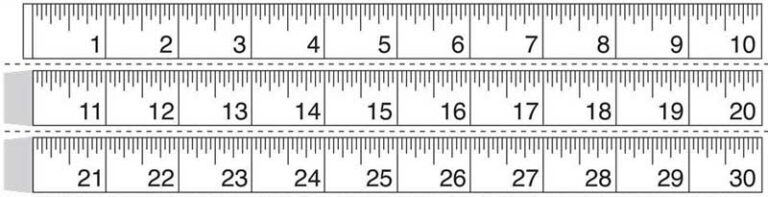

– Size and shape: Labels come in a range of sizes and shapes, allowing businesses to select the perfect fit for their products and packaging.

– Material: Zebra print labels can be made from various materials, such as paper, vinyl, and plastic, each with its own unique properties and durability.

– Printing techniques: Labels can be printed using digital, offset, or flexographic printing methods, resulting in different levels of quality and cost-effectiveness.

Creative and Effective Designs

Businesses can showcase their creativity and effectively convey their message through innovative zebra print label designs. Some examples include:

– Bold and vibrant colors: Using bright and contrasting colors can make labels stand out and grab attention.

– Unique patterns: Incorporating intricate or abstract patterns can add visual interest and create a memorable brand image.

– Custom typography: Designing labels with unique fonts and typefaces can enhance readability and reflect the brand’s personality.

– Interactive elements: Adding QR codes or augmented reality features can provide customers with additional information or engage them with interactive experiences.

By leveraging these customization options, businesses can create zebra print labels that not only enhance their products but also effectively communicate their brand identity and meet their specific labeling needs.

Industry Trends and Future Prospects

The zebra print label industry is experiencing a surge in popularity, driven by the resurgence of the zebra print trend in fashion and home decor.

Emerging trends include the use of metallic inks, holographic effects, and 3D printing techniques to create eye-catching and visually appealing labels.

Growth Opportunities and Challenges

- Growth opportunities: Expanding applications in fashion, retail, and packaging, as well as the increasing demand for sustainable and eco-friendly labels.

- Challenges: Rising competition from digital printing technologies and the need for continuous innovation to stay ahead in the market.

Future Direction of Label Design and Technology

The future of zebra print labels lies in the integration of advanced technologies, such as RFID (Radio Frequency Identification) and NFC (Near Field Communication), to enhance functionality and provide interactive experiences.

Additionally, the focus on sustainability will continue to drive the development of eco-friendly materials and printing processes.

Frequently Asked Questions

What are the most common materials used for Zebra Print Labels?

Zebra Print Labels are typically made from durable materials such as vinyl, polyester, and polypropylene, ensuring longevity and resistance to wear and tear.

How can businesses customize Zebra Print Labels to meet their specific needs?

Zebra Print Labels offer a wide range of customization options, including size, shape, color, pattern, and even the addition of unique elements like QR codes or RFID chips.

What are the advantages of using Zebra Print Labels?

Zebra Print Labels offer numerous advantages, including enhanced product recognition, increased brand visibility, improved operational efficiency, and the ability to capture the attention of consumers.

Are there any drawbacks or limitations to using Zebra Print Labels?

While Zebra Print Labels offer many benefits, they may not be suitable for all applications. Factors to consider include the cost of production, the potential for visual clutter, and the need for specialized printing equipment.

What are the emerging trends in the Zebra Print Label industry?

The Zebra Print Label industry is constantly evolving, with trends such as the use of sustainable materials, the integration of smart technology, and the exploration of new design techniques shaping the future of these labels.