Printable Labels Waterproof: The Ultimate Guide to Durable Labeling

In the world of labeling, durability is paramount. Printable labels waterproof offer a solution to the challenges posed by moisture, spills, and harsh environments. Whether you’re a manufacturer, retailer, or simply seeking to organize your home, this guide will delve into the fascinating world of waterproof labels, exploring their composition, printing methods, design considerations, applications, and market trends.

From the chemical composition that ensures their resilience to the innovative printing techniques that guarantee crisp and long-lasting images, we’ll uncover the secrets behind these remarkable labels. Get ready to revolutionize your labeling game with this comprehensive guide to printable labels waterproof.

Waterproof Material Composition

Waterproof printable labels are made from a variety of materials, each with its own unique properties. The most common materials used are:

- Vinyl: Vinyl is a durable, waterproof material that is resistant to tearing and abrasion. It is also UV-resistant, so it will not fade or discolor over time.

- Polyester: Polyester is a strong, waterproof material that is also resistant to chemicals and solvents. It is a good choice for labels that will be exposed to harsh conditions.

- Polypropylene: Polypropylene is a lightweight, waterproof material that is resistant to moisture and chemicals. It is a good choice for labels that will be used in food or beverage applications.

The type of material used for a waterproof printable label will depend on the specific application. For example, if the label will be used outdoors, a durable material like vinyl or polyester is a good choice. If the label will be used in a food or beverage application, a material like polypropylene is a good choice.

Printing Methods for Waterproof Labels

In the realm of waterproof labels, the choice of printing method plays a pivotal role in ensuring their durability and resistance to various environmental conditions. Dive into the nitty-gritty of different printing techniques, their pros and cons, and compatible equipment to make an informed decision for your specific labeling needs.

Digital Printing

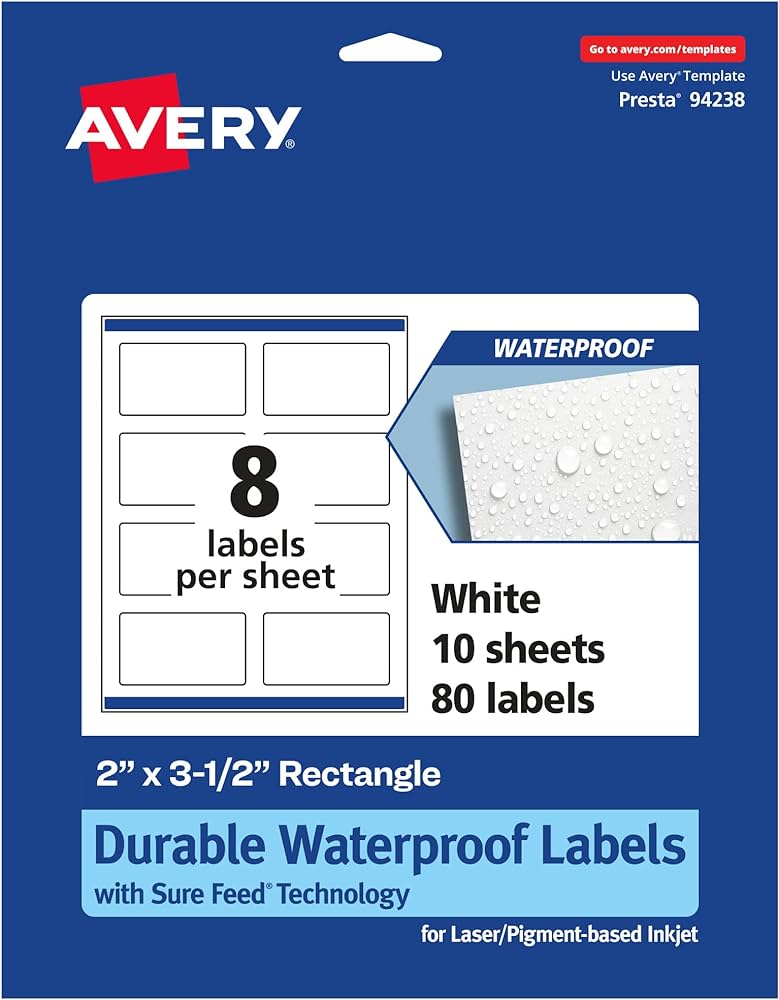

Digital printing, a trendy method for waterproof labels, utilizes inkjet or laser printers to transfer digital images directly onto the label material. It’s a versatile technique that allows for quick and easy customization, making it ideal for small-scale production and personalized labels. However, digital printing may not be the most economical option for large-scale printing runs.

Flexography

Flexography, a popular choice for high-volume printing, employs flexible printing plates to transfer ink onto the label material. This method excels in producing vibrant and detailed prints with a high level of durability. Flexography is commonly used in commercial applications, such as packaging and product labeling, due to its cost-effectiveness for large print runs.

Screen Printing

Screen printing, a time-tested technique, involves forcing ink through a mesh screen onto the label material. It’s a durable and versatile method that produces bold, vibrant prints. Screen printing is often used for specialized applications, such as printing on curved surfaces or creating tactile effects on labels.

Offset Printing

Offset printing, a traditional method, uses metal plates to transfer ink onto rubber rollers, which then transfer the ink onto the label material. It’s a high-quality printing technique that produces sharp, detailed prints with excellent color accuracy. Offset printing is commonly used for large-scale printing runs, such as commercial packaging and product labels.

Printers and Inks for Waterproof Labels

When selecting a printer for waterproof labels, consider the following factors: print quality, speed, durability, and compatibility with waterproof materials. Epson, HP, and Canon are reputable brands that offer a range of printers suitable for printing on waterproof labels.

For waterproof labels, it’s crucial to use inks specifically designed for this purpose. These inks are formulated to resist water, chemicals, and UV radiation, ensuring the longevity and integrity of your labels.

Design Considerations for Waterproof Labels

Designing waterproof labels that are both visually appealing and functional requires careful consideration.

Font size, color contrast, and layout play crucial roles in creating effective labels. Choose fonts that are easily readable from a distance, even when wet. Ensure sufficient contrast between the font color and the label background for maximum visibility. A well-organized layout guides the reader’s eye through the label’s content effortlessly.

Font Size

Use a font size that is large enough to be read easily, especially when the label is wet. A good rule of thumb is to use a font size of at least 10 points.

Color Contrast

Choose colors that contrast well with each other. This will make the text on the label easier to read. For example, you could use black text on a white background, or white text on a black background.

Layout

The layout of the label should be clear and concise. Use headings and subheadings to organize the information on the label. And make sure to leave enough white space around the text so that it’s easy to read.

Applications and Industries for Waterproof Labels

Waterproof labels find widespread application across various industries due to their durability and resistance to moisture and environmental factors.

Automotive Industry

Waterproof labels are essential for vehicles, providing vital information such as vehicle identification numbers (VINs), tire pressure, and maintenance schedules. They withstand harsh conditions like rain, snow, and car washes, ensuring the information remains legible throughout the vehicle’s lifespan.

Manufacturing

In manufacturing, waterproof labels play a crucial role in product identification and tracking. They are used to label products with barcodes, serial numbers, and other important information that must remain intact despite exposure to water, chemicals, or extreme temperatures.

Pharmaceutical Industry

Waterproof labels are vital in the pharmaceutical industry, where they are used to label vials, bottles, and packaging. They ensure the integrity of critical information such as drug dosage, storage conditions, and expiration dates, preventing potential medication errors.

Outdoor and Recreation

Waterproof labels are essential for outdoor equipment, such as camping gear, hiking backpacks, and fishing rods. They provide important information like product specifications, instructions, and safety warnings that remain visible even in wet or muddy conditions.

Food and Beverage Industry

In the food and beverage industry, waterproof labels are used on product packaging to provide information such as ingredients, nutritional value, and storage instructions. They resist moisture and condensation, ensuring consumers have access to vital information throughout the product’s shelf life.

Waterproof Label Market Analysis

The waterproof label market is experiencing steady growth due to the increasing demand for durable and weather-resistant labels in various industries. The market is projected to reach $X billion by 2028, driven by the growing adoption of waterproof labels in packaging, food & beverage, and healthcare applications.

Key players in the waterproof label industry include Avery Dennison, UPM Raflatac, and CCL Industries. These companies offer a wide range of waterproof label materials, including synthetic papers, vinyl, and polyester. They also provide custom printing and finishing services to meet specific customer requirements.

Growth Opportunities

- Increasing demand for durable labels in harsh environments

- Growth in the e-commerce sector, driving demand for waterproof shipping labels

- Expansion of the healthcare industry, requiring waterproof labels for medical devices and packaging

Challenges

- Fluctuating raw material prices

- Competition from low-cost manufacturers

- Environmental regulations on plastic and paper materials

Questions and Answers

What is the lifespan of waterproof labels?

The lifespan of waterproof labels varies depending on the materials used and the environmental conditions they are exposed to. However, high-quality waterproof labels can last for several years, even in harsh outdoor environments.

Can waterproof labels be printed on any type of printer?

No, not all printers are compatible with waterproof labels. You will need a printer that is specifically designed for printing on waterproof materials. Inkjet printers are a popular choice for printing waterproof labels.

What is the best way to design waterproof labels?

When designing waterproof labels, it’s important to consider the size, color contrast, and layout. Use large, easy-to-read fonts and high-contrast colors to ensure visibility. Keep the design simple and avoid cluttering it with unnecessary elements.