Printable Iron On Vinyl: Elevate Your Designs with Versatility and Durability

In the realm of customization and creativity, Printable Iron On Vinyl (PIV) emerges as an indispensable tool for transforming ordinary surfaces into vibrant masterpieces. This versatile material empowers you to unleash your imagination and imprint your unique designs onto a wide range of fabrics and objects, opening up endless possibilities for self-expression and professional applications.

Composed of durable polymers, PIV boasts an array of properties that make it an exceptional choice for both personal and commercial projects. Its exceptional adhesion ensures long-lasting results, while its resistance to fading, cracking, and peeling guarantees the longevity of your creations. The diversity of PIV types, including heat transfer vinyl, inkjet printable vinyl, and laser printable vinyl, caters to various printing methods and design requirements.

Printable Iron-On Vinyl Overview

Printable Iron-On Vinyl (also known as Printable Heat-Transfer Vinyl or Printable HTV) is a special type of vinyl that allows you to print your own designs onto it using a regular inkjet printer.

It is made from a durable, heat-resistant material that can withstand the heat of an iron or heat press. Once printed, the design can be easily transferred onto fabric, creating a permanent and vibrant print.

Types of Printable Iron-On Vinyl

There are two main types of Printable Iron-On Vinyl:

- Light Printable Iron-On Vinyl: This type is designed to be used on light-coloured fabrics. It is available in a variety of finishes, including matte, glossy, and metallic.

- Dark Printable Iron-On Vinyl: This type is designed to be used on dark-coloured fabrics. It is typically made with a white or clear backing that helps the design to show up on darker fabrics.

Applications of Printable Iron-On Vinyl

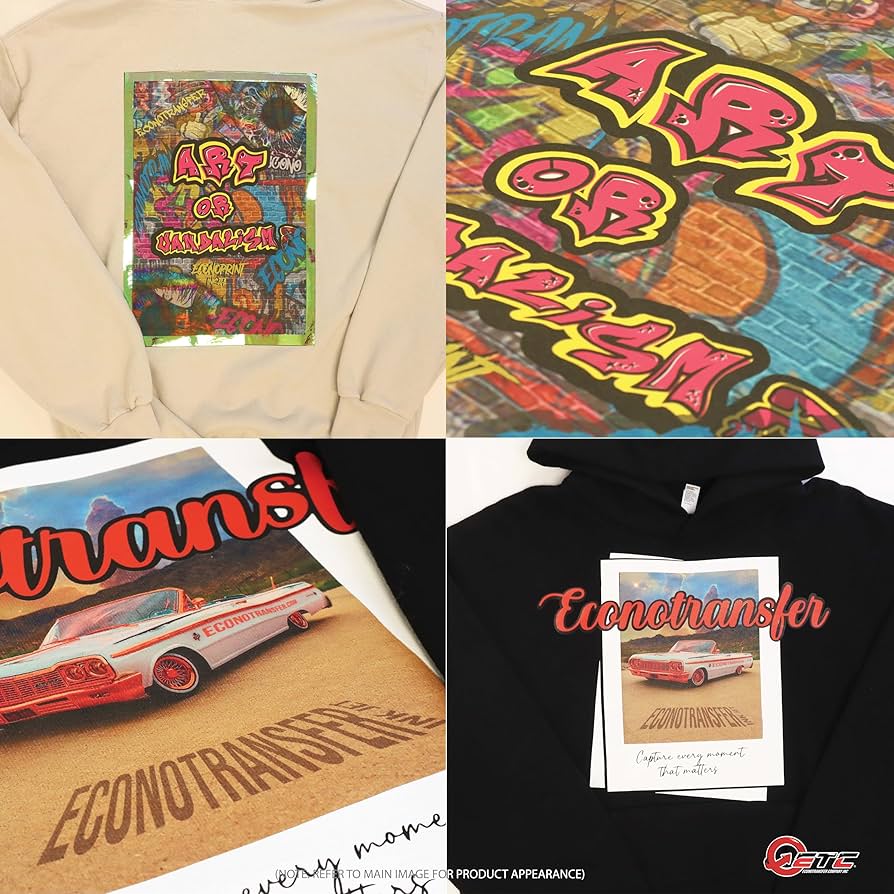

Printable Iron-On Vinyl is a versatile material with a wide range of applications. It’s commonly used in the clothing industry to create custom T-shirts, hoodies, and other garments. But it’s also used in other industries, such as home décor, crafting, and even signage.

Versatility and Adaptability

One of the great things about Printable Iron-On Vinyl is that it can be used on a variety of materials, including cotton, polyester, and even leather. This makes it a great choice for a wide range of projects. It’s also very easy to use. Just print your design onto the vinyl, cut it out, and iron it onto your chosen material.

Creative and Innovative Applications

In addition to its traditional uses, Printable Iron-On Vinyl can also be used for more creative and innovative applications. For example, you can use it to create custom wall art, decorate furniture, or even make your own jewelry. The possibilities are endless.

Examples of Use

Here are a few examples of how Printable Iron-On Vinyl is being used in different industries:

– In the clothing industry, it’s used to create custom T-shirts, hoodies, and other garments.

– In the home décor industry, it’s used to create custom curtains, pillows, and other home accessories.

– In the crafting industry, it’s used to create custom cards, scrapbook pages, and other paper crafts.

– In the signage industry, it’s used to create custom signs, banners, and other marketing materials.

Benefits of Using Printable Iron-On Vinyl

Bless your creative socks, Printable Iron-On Vinyl is a right proper game-changer when it comes to decking out your garms. Compared to other materials, it’s like the VIP of customization, bringing durability, longevity, and bang for your buck that’ll make your designs stand out like a boss.

Durability

Printable Iron-On Vinyl is tougher than a bulldog chewing on a bone. It can handle the rough and tumble of daily wear and tear, making it the perfect choice for tees, hoodies, and anything else that needs to withstand the rigors of life.

Longevity

Forget about designs that fade faster than a politician’s promises. Printable Iron-On Vinyl keeps its colors vibrant and sharp, even after countless washes. Your creations will stay looking fresh for years to come, without losing their swagger.

Cost-Effectiveness

Who says looking fly has to break the bank? Printable Iron-On Vinyl is a total bargain. It’s cheaper than other materials, but doesn’t skimp on quality. You’ll get more bang for your buck and still end up with designs that turn heads.

Testimonials

“I’ve used Printable Iron-On Vinyl on everything from T-shirts to tote bags, and it’s never let me down. The designs are always sharp, durable, and I’ve never had any issues with fading or peeling.” – Sally, a satisfied crafter

Designing with Printable Iron-On Vinyl

Designing with printable iron-on vinyl allows for endless creative possibilities. To create eye-catching graphics, consider the following guidelines:

Choosing Software and Techniques

Select design software that suits your skill level and project requirements. Popular options include Adobe Photoshop, Illustrator, and free alternatives like GIMP or Inkscape. Use vector-based software for sharp and scalable designs.

Optimizing for Printability

Ensure your designs are high-resolution (300 dpi or higher) to prevent pixelation. Use a CMYK color profile for accurate color reproduction. Consider the size and placement of your design on the garment.

Tips for Application

Mirror your design before printing if applying to dark-colored fabrics. Use a heat press or iron for optimal adhesion. Follow the manufacturer’s instructions for specific application techniques.

Printing and Application Techniques

Printing Printable Iron-On Vinyl is a straightforward process that can be done with a variety of printers and inks. The most common type of printer used for this purpose is an inkjet printer, but laser printers can also be used. The type of ink used will depend on the type of printer you are using. Inkjet printers require water-based inks, while laser printers require toner-based inks.

Once you have chosen your printer and ink, you will need to prepare your Printable Iron-On Vinyl for printing. This involves cutting the vinyl to the desired size and shape and then peeling away the backing paper. Once the vinyl is prepared, you can load it into your printer and print your design.

After your design has been printed, you will need to allow it to dry completely. This can take anywhere from a few minutes to a few hours, depending on the type of ink and printer you are using. Once the design is dry, you can apply it to your desired surface.

Applying Printable Iron-On Vinyl is a simple process that can be done with a household iron. First, you will need to preheat your iron to the desired temperature. The temperature will vary depending on the type of vinyl you are using, so be sure to check the manufacturer’s instructions.

Once your iron is preheated, you can place the Printable Iron-On Vinyl on your desired surface. Be sure to position the vinyl correctly, as it will be difficult to move once it has been applied. Once the vinyl is in place, you can use your iron to press down on it firmly. The pressure and heat from the iron will cause the vinyl to adhere to the surface.

After you have applied the Printable Iron-On Vinyl, you will need to allow it to cool completely. This will help to ensure that the vinyl adheres properly to the surface. Once the vinyl is cool, you can enjoy your custom-designed item!

Troubleshooting

If you are having trouble printing or applying Printable Iron-On Vinyl, there are a few things you can try. First, make sure that you are using the correct type of printer and ink for the vinyl you are using. Second, check the manufacturer’s instructions for specific printing and application instructions. Finally, if you are still having trouble, you can contact the manufacturer of the vinyl for assistance.

Care and Maintenance of Printable Iron-On Vinyl

Keep your Printable Iron-On Vinyl looking fresh and vibrant with these top tips.

Washing

– Machine wash inside out on a gentle cycle with cold water.

– Use a mild detergent and avoid bleach or fabric softeners.

Drying

– Tumble dry on low heat or hang to dry.

– Avoid high heat, as this can damage the vinyl.

Storing

– Store items with Printable Iron-On Vinyl in a cool, dry place.

– Fold or roll them gently to avoid creasing or cracking the vinyl.

Tips for Extending Lifespan

– Iron the vinyl on a low heat setting with a pressing cloth or parchment paper.

– Avoid ironing directly on the vinyl.

– Wash garments with Printable Iron-On Vinyl less frequently to preserve the design.

Industry Trends and Innovations

The Printable Iron-On Vinyl industry is rapidly evolving, with emerging trends and innovations shaping its future.

One notable trend is the increasing demand for eco-friendly and sustainable materials. Customers are becoming more conscious of the environmental impact of their purchases, leading to a surge in the popularity of biodegradable and recyclable printable iron-on vinyl.

Another trend is the rise of digital printing technologies. Advanced printers now offer high-resolution printing capabilities, enabling intricate and vibrant designs to be transferred onto fabrics. This has opened up new possibilities for personalized and customized garments.

Furthermore, the industry is witnessing the development of innovative applications for printable iron-on vinyl. From heat-activated adhesive films to glow-in-the-dark and reflective materials, these advancements are expanding the creative potential of printable iron-on vinyl.

As technology continues to advance, we can expect to see further innovations in the Printable Iron-On Vinyl industry. These advancements will empower designers, crafters, and businesses to create unique and eye-catching designs, transforming the way we personalize and decorate fabrics.

Common Queries

What are the different types of Printable Iron On Vinyl?

PIV comes in various types, including heat transfer vinyl, inkjet printable vinyl, and laser printable vinyl. Each type is designed for specific printing methods and materials.

How do I design for Printable Iron On Vinyl?

Effective PIV designs require high-quality graphics, optimized for printability and application. Consider using design software and techniques that ensure crisp lines, vibrant colors, and appropriate sizing.

What are the care instructions for Printable Iron On Vinyl?

To maintain the longevity of your PIV creations, follow proper care instructions. Wash items gently in cold water, avoid harsh detergents, and tumble dry on low heat or air dry. Avoid ironing directly on the PIV.

Can I use Printable Iron On Vinyl on any fabric?

While PIV adheres well to most fabrics, it’s essential to test a small area first to ensure compatibility. Delicate fabrics or those with special coatings may require special application techniques.