Printable Class 9 Lithium Battery Label: A Comprehensive Guide

In the realm of hazardous materials transportation, lithium batteries pose unique challenges. Proper labeling is paramount to ensure the safety of handlers, carriers, and the general public. This guide delves into the intricacies of printable Class 9 lithium battery labels, providing a comprehensive understanding of their design, materials, regulations, and best practices.

From understanding the specific information required on the label to exploring the various materials and printing methods available, this guide empowers you with the knowledge to create compliant and effective labels. Additionally, it sheds light on the importance of label durability, compliance with regulations, and provides real-world examples to illustrate the practical application of these principles.

Label Design and Specifications

Lithium battery labels must meet specific design requirements to ensure they are easily identifiable and provide all necessary information. The label should be clearly visible and securely attached to the battery pack or device containing the battery. The label must be resistant to wear, tear, and environmental conditions, such as moisture and temperature fluctuations.

The following information must be included on the label:

- UN number: UN3480

- Battery type: Lithium-ion or lithium-metal

- Nominal voltage: Voltage of the battery

- Watt-hours: Energy content of the battery

- Manufacturer’s name and address

- Country of origin

The label should also include a symbol that indicates the battery is a lithium battery. The symbol must be black and white, and it must be at least 12 mm in diameter.

Well-designed labels use clear and concise language, and they are easy to read and understand. The label should be placed on the battery pack or device in a prominent location. It should be visible from all sides of the battery pack or device.

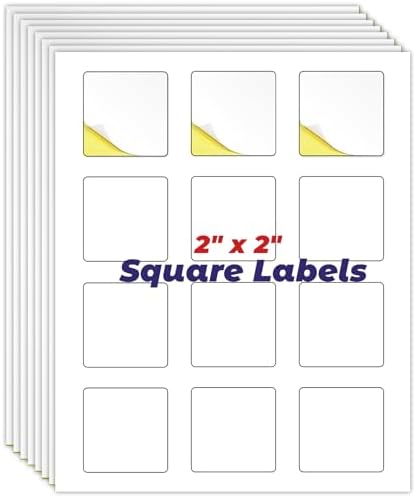

Materials and Printing Methods

Selecting the right materials and printing methods is crucial for creating durable, water-resistant, and cost-effective class 9 lithium battery labels. Various materials offer different advantages, while printing methods vary in terms of quality, speed, and cost.

Materials

- Polypropylene (PP): Highly durable, water-resistant, and cost-effective. Ideal for labels exposed to moisture and harsh environments.

- Polyethylene (PE): Flexible, lightweight, and water-resistant. Suitable for labels requiring flexibility and adhesion to curved surfaces.

- Vinyl: Strong, durable, and highly water-resistant. Often used for labels exposed to extreme temperatures and chemicals.

- Paper: Cost-effective and easy to print, but not as durable or water-resistant as other materials. Suitable for indoor use.

Printing Methods

- Flexography: A high-speed printing method using flexible printing plates. Produces high-quality labels at a relatively low cost.

- Offset Printing: A high-quality printing method that uses metal plates. Provides excellent color accuracy and resolution but can be more expensive than other methods.

- Digital Printing: A computer-controlled printing method that produces labels directly from digital files. Offers flexibility and customization but may have higher costs for large quantities.

Recommendations

For durable and water-resistant labels, choose PP or vinyl. Flexography is a suitable printing method for large quantities, while offset printing provides high-quality results for smaller quantities. Digital printing is ideal for small-scale production and customization.

Compliance and Regulations

Printing class 9 lithium battery labels involves adherence to strict regulations and standards to ensure safety and compliance. Understanding and adhering to these requirements is paramount to avoid potential legal liabilities and ensure the safe handling and transportation of lithium batteries.

Failure to comply with these regulations can result in penalties, including fines, product recalls, and even criminal charges. It’s crucial to stay updated on the latest regulations and ensure that your labels meet the required specifications.

Key Regulations and Standards

| Regulation/Standard | Issuing Body | Purpose |

|---|---|---|

| UN Model Regulations on the Transport of Dangerous Goods | United Nations | Sets global standards for the transportation of dangerous goods, including lithium batteries |

| IATA Dangerous Goods Regulations (DGR) | International Air Transport Association | Specific regulations for the air transport of dangerous goods, including lithium batteries |

| IMDG Code | International Maritime Organization | Regulations for the maritime transport of dangerous goods, including lithium batteries |

| ANSI MH26.3-2019 | American National Standards Institute | Standard for the marking and labeling of lithium batteries |

| GB/T 31484-2015 | Chinese National Standard | Standard for the labeling of lithium batteries |

Label Content and Placement

Ensure that the printable Class 9 lithium battery label contains all necessary information clearly and concisely. Avoid using jargon or technical terms that may not be easily understood by the general public. Keep the language simple and straightforward, making the label easy to read and comprehend at a glance.

Label Content

The label should include the following specific content:

- The United Nations (UN) number for lithium batteries: UN3480

- The battery type: lithium metal or lithium-ion

- The nominal voltage of the battery

- The watt-hours (Wh) rating of the battery

- The manufacturer’s name and address

- The contact information for the manufacturer or importer

- The statement: “This battery may present a fire or explosion hazard if mishandled.”

Label Placement

Place the label on the battery or its packaging in a conspicuous location that is easily visible and accessible. The label should be securely attached and not easily removed or obscured. Choose a location where the label will not be damaged or become illegible during normal handling and transportation.

Label Design and Layout

Design the label using clear and contrasting colors and fonts to enhance readability. Use a font size that is large enough to be easily read from a distance. Consider using symbols or graphics to convey important information, but ensure they are clear and unambiguous. Keep the label layout organized and uncluttered, avoiding unnecessary text or graphics that may distract from the essential information.

Label Durability and Testing

Labels on lithium batteries need to be durable to withstand the intended use and environment. Factors that can affect label durability include abrasion, water, and temperature.

There are different tests that can be performed to assess label durability. These tests include abrasion resistance, water resistance, and temperature resistance.

Abrasion Resistance

Abrasion resistance tests assess the ability of a label to resist wear and tear. This is important for labels that will be subjected to frequent handling or contact with other objects.

There are different methods for testing abrasion resistance. One common method is the Taber Abrasion Test. This test uses a rotating abrasive wheel to rub against the label surface. The number of cycles required to wear through the label is recorded as the abrasion resistance.

Water Resistance

Water resistance tests assess the ability of a label to resist water damage. This is important for labels that will be exposed to moisture or water. There are different methods for testing water resistance. One common method is the Water Immersion Test. This test involves submerging the label in water for a specified period of time. The label is then inspected for any signs of damage, such as peeling, fading, or smudging.

Temperature Resistance

Temperature resistance tests assess the ability of a label to withstand extreme temperatures. This is important for labels that will be exposed to high or low temperatures. There are different methods for testing temperature resistance. One common method is the Temperature Cycling Test. This test involves cycling the label between high and low temperatures for a specified number of cycles. The label is then inspected for any signs of damage, such as cracking, peeling, or delamination.

By performing these tests, manufacturers can ensure that their labels are durable enough to withstand the intended use and environment.

Case Studies and Examples

To further solidify our understanding of effective printable Class 9 lithium battery labels, let’s dive into some real-world examples and case studies.

Case Study 1: Successful Label Design

One notable case study involves a leading electronics manufacturer that implemented a highly effective printable Class 9 lithium battery label. The label featured:

- Clear and concise hazard symbols and warnings

- Durable materials that withstood transportation and handling

- High-quality printing that ensured legibility and longevity

This label’s success stemmed from its adherence to regulatory requirements, its use of appropriate materials and printing methods, and its focus on user safety.

Case Study 2: Ineffective Label Design

Conversely, another case study highlights the consequences of poorly designed labels. A manufacturer used a low-quality label that lacked proper hazard warnings. This resulted in:

- Confusion and misunderstanding among handlers

- Increased risk of accidents and injuries

- Non-compliance with regulatory standards

This case emphasizes the importance of investing in high-quality, compliant labels to ensure safety and regulatory compliance.

Lessons Learned

These case studies underscore the following lessons:

- Comply with all relevant regulations and standards

- Use durable materials and high-quality printing methods

- Design labels that are clear, concise, and easy to understand

- Regularly review and update labels to ensure accuracy and compliance

FAQ Corner

What are the key elements that must be included on a Class 9 lithium battery label?

A Class 9 lithium battery label must prominently display the UN number, battery type, net weight or capacity, and the manufacturer’s name and address.

What materials are commonly used for printing Class 9 lithium battery labels?

Common materials include BOPP (biaxially oriented polypropylene), PET (polyethylene terephthalate), and vinyl. Each material offers unique advantages in terms of durability, water resistance, and cost.

How can I ensure that my Class 9 lithium battery labels are durable enough to withstand the intended use and environment?

Labels should be tested for abrasion resistance, water resistance, and temperature resistance to ensure they can withstand the rigors of transportation and handling.

What are the potential consequences of non-compliance with Class 9 lithium battery labeling regulations?

Non-compliance can result in fines, penalties, and even criminal charges. It can also jeopardize the safety of handlers, carriers, and the public.