Printable Brackets: The Ultimate Guide to 3D Printed Support Structures

Welcome to the world of printable brackets, where the boundaries of design and functionality converge. These 3D printed wonders are revolutionizing the way we approach prototyping, manufacturing, and construction, offering limitless possibilities for customization and innovation.

Printable brackets are not just ordinary brackets; they are versatile tools that can be tailored to your specific needs. From lightweight and flexible designs to heavy-duty brackets capable of supporting substantial loads, the options are endless. Join us as we delve into the captivating world of printable brackets, exploring their types, materials, design considerations, and countless applications.

Overview of Printable Brackets

Printable brackets are templates that provide a structured format for organizing and visualizing tournament or competition schedules. They consist of a series of lines and boxes that represent the different stages and matchups within a competition. Printable brackets are widely used in various sports, including basketball, football, and tennis, as well as in other competitive events such as debates or academic competitions. They offer a clear and concise way to track the progress of a tournament and determine the winners and losers.

The popularity of printable brackets stems from their versatility and ease of use. They can be easily customized to fit the specific requirements of any tournament or competition, making them suitable for events of all sizes and formats. Additionally, printable brackets can be easily printed and distributed to participants and spectators, providing a tangible reference point for following the competition.

Types of Printable Brackets

Yo, check it, there’s a whole bunch of different types of printable brackets out there, each with its own sick features and uses. Let’s dive in, shall we?

Whether you’re organizing a footy tournament or just want to sort out your mates’ opinions on the best Nandos flavour, there’s a bracket that’ll do the trick.

Single-elimination Brackets

These bad boys are all about the knockout round, fam. Once you lose, you’re out. It’s like the Hunger Games for brackets. Perfect for tournaments where there can only be one winner.

Double-elimination Brackets

Double-elimination brackets give losers a second chance to redeem themselves. You’ll have two brackets: the winners’ bracket and the losers’ bracket. If you lose in the winners’ bracket, you drop down to the losers’ bracket. But if you lose in the losers’ bracket, you’re out for good.

Round-robin Brackets

Round-robin brackets are all about fairness, bruv. Every team or competitor plays each other once. The team with the most wins at the end takes the crown.

Swiss Brackets

Swiss brackets are the ultimate test of skill. You’ll play against opponents with similar records, so you’re always facing a challenge. The top players rise to the top, while the weaker ones sink to the bottom.

Hybrid Brackets

Hybrid brackets mix and match different types of brackets to create something unique. For example, you could have a single-elimination bracket for the top teams and a double-elimination bracket for the rest.

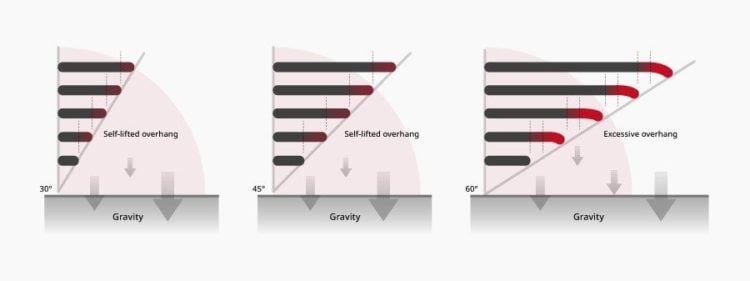

Materials and Design Considerations

When creating printable brackets, choosing the right materials and considering design factors is crucial for achieving the desired strength, durability, and aesthetics.

Materials

Printable brackets are typically made from various materials, including:

- Paper: Lightweight and cost-effective, suitable for temporary or decorative purposes.

- Cardstock: Thicker and more durable than paper, ideal for heavier-duty applications.

- Plastic: Durable and weather-resistant, suitable for outdoor or long-term use.

- Metal: Strongest and most durable, ideal for heavy-duty applications.

Design Considerations

Apart from material selection, design considerations also play a vital role in the functionality and aesthetics of printable brackets. Factors to consider include:

- Strength: The bracket’s ability to withstand loads without breaking or deforming.

- Durability: Resistance to wear, tear, and environmental factors over time.

- Aesthetics: The bracket’s appearance and how it complements its surroundings.

Choosing the Right Material and Design

Selecting the appropriate material and design depends on the specific application. For example, if the bracket will be used to support heavy objects or in an outdoor environment, a durable material like metal or plastic is recommended. For temporary or decorative purposes, paper or cardstock may suffice.

Printable Bracket Customization

Customize your printable brackets to match your team spirit, event theme, or personal style. Design software and online tools provide templates and editing features to create personalized brackets.

Incorporating Logos and Graphics

Add a personal touch to your brackets by incorporating logos, graphics, or images. Use design software to import these elements or browse online libraries for pre-designed options. Ensure that the images are high-quality and fit within the bracket design.

Printing and Assembly s

To create sturdy and functional printable brackets, proper printing and assembly are crucial. This involves selecting the appropriate printing method and materials, ensuring precise alignment, and maintaining stability during assembly.

Various printing methods offer distinct advantages and drawbacks. Fused Deposition Modeling (FDM) is widely accessible and cost-effective, but may result in visible layer lines. Stereolithography (SLA) produces smooth, high-resolution prints, yet requires specialized equipment and materials. Selective Laser Sintering (SLS) offers robust parts with intricate geometries, but can be expensive.

Alignment and Stability Tips

- Use a high-quality printer with accurate calibration to minimize printing errors.

- Ensure the print bed is level and clean to prevent warping or shifting during printing.

- Check the bracket’s dimensions against the design specifications before assembly.

- Use a jig or alignment tool to ensure precise positioning of components during assembly.

- Apply adhesives or fasteners securely to maintain stability and prevent the bracket from becoming loose or wobbly.

Applications of Printable Brackets

Printable brackets offer versatile solutions across various industries and settings. They are widely used in prototyping, manufacturing, construction, and DIY projects.

Prototyping

- Creating quick and inexpensive prototypes for testing and design iteration.

- Enabling rapid prototyping of complex geometries and custom designs.

Manufacturing

- Producing custom brackets for specific equipment or machinery.

- Creating jigs and fixtures for assembly and production processes.

Construction

- Fabricating brackets for mounting shelves, lighting fixtures, and other architectural elements.

- Creating custom supports for piping, ductwork, and other infrastructure.

DIY Projects

- Building custom shelves, furniture, and other home décor items.

- Creating brackets for mounting tools, electronics, and other equipment in workshops and garages.

Case Study:

A small manufacturing company used printable brackets to create custom mounting solutions for their new product line. By 3D printing the brackets, they were able to quickly iterate on designs, reduce production costs, and meet specific customer requirements.

FAQ

What materials are commonly used for printable brackets?

PLA, ABS, PETG, and TPU are commonly used materials for printable brackets due to their durability, strength, and versatility.

Can I customize the design of my printable brackets?

Yes, you can customize the design using design software or online tools to incorporate logos, graphics, or other elements that suit your specific requirements.

What factors should I consider when designing printable brackets?

Strength, durability, aesthetics, and the intended application are crucial factors to consider when designing printable brackets to ensure they meet your functional and aesthetic needs.