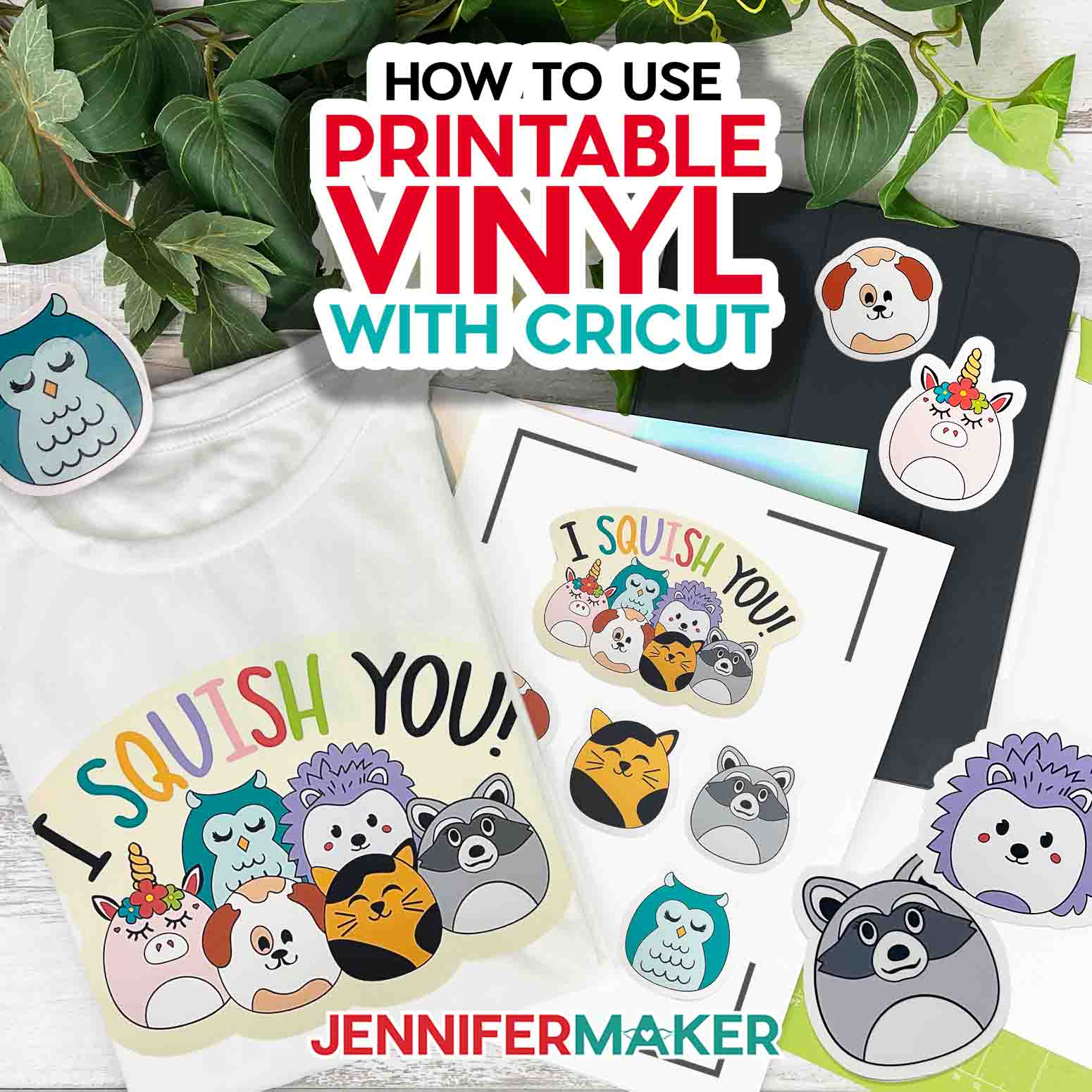

How to Print on Printable Vinyl: A Comprehensive Guide

Printable vinyl is a versatile material that offers endless possibilities for customization and decoration. Whether you’re a hobbyist, a small business owner, or a professional designer, learning how to print on printable vinyl can open up a world of creative opportunities.

In this guide, we will cover everything you need to know about printing on printable vinyl, from choosing the right materials to troubleshooting common problems. By following these steps, you’ll be able to create high-quality prints that will last for years to come.

Introduction

Printable vinyl is a kind of self-adhesive plastic material that you can print on with a regular inkjet or laser printer. It’s a versatile material that can be used for a wide range of projects, from custom stickers and labels to T-shirts and tote bags.

There are many benefits to using printable vinyl. It’s durable, waterproof, and fade-resistant, so it’s perfect for outdoor use. It’s also easy to cut and apply, so you can create professional-looking projects in no time.

Benefits of Using Printable Vinyl

Here are some of the benefits of using printable vinyl:

- Durable: Printable vinyl is made of a durable plastic material that is resistant to tearing and fading.

- Waterproof: Printable vinyl is waterproof, so it can be used for outdoor projects without worrying about it getting damaged by the rain.

- Fade-resistant: Printable vinyl is fade-resistant, so your projects will look great for years to come.

- Easy to cut and apply: Printable vinyl is easy to cut and apply, so you can create professional-looking projects in no time.

- Versatile: Printable vinyl can be used for a wide range of projects, from custom stickers and labels to T-shirts and tote bags.

Materials and Equipment

Grab all the bits and bobs you’ll need to get your vinyl printing game on point. We’ll break it down into the essentials and give you the lowdown on choosing the right gear.

Essential Materials

- Printable Vinyl: Get your hands on some high-quality vinyl that’s made for printing. Choose the right type for your project, whether it’s glossy, matte, or transparent.

- Inkjet Printer: Invest in an inkjet printer that’s compatible with vinyl printing. Make sure it has the right settings and ink cartridges for the job.

- Cutting Machine: If you’re going all out, a cutting machine will help you shape and cut your vinyl designs with precision.

Choosing the Right Gear

Picking the perfect materials and equipment is crucial. Here’s how to make the right choices:

- Vinyl Type: Consider the surface you’ll be applying the vinyl to and choose a type that’s durable and suitable.

- Printer Quality: Go for a printer with high resolution and vibrant colors to get sharp and professional-looking prints.

- Cutting Machine Features: Look for a cutting machine that offers precision cutting, adjustable depth, and compatibility with different vinyl types.

Design and Preparation

Designing for printable vinyl involves creating a digital file that will be used to print the design onto the vinyl material. The design process typically starts with creating a new document in a design software program, such as Adobe Photoshop or Illustrator. The size of the document should be set to the desired dimensions of the printed vinyl.

Once the document is created, you can begin designing your artwork. Printable vinyl can be printed in full color, so you can use any colors or images you want. However, it is important to keep in mind that the colors you see on your computer screen may not be the same as the colors that are printed on the vinyl. This is because different printers use different color profiles. To ensure that your colors are accurate, it is important to calibrate your printer before printing.

Preparing the Design for Printing

Once you have finished designing your artwork, you need to prepare it for printing. This involves converting the design to a format that is compatible with your printer. Most printers use a format called PDF (Portable Document Format). You can convert your design to PDF using a program such as Adobe Acrobat.

Once your design is converted to PDF, you need to check the file size. The file size should be less than the maximum file size that your printer can handle. If the file size is too large, you may need to reduce the resolution of the images in your design.

You should also check the bleed area of your design. The bleed area is the area of the design that will be trimmed off after printing. It is important to make sure that all of your important design elements are within the bleed area.

Once you have checked the file size and the bleed area, you are ready to print your design onto printable vinyl.

Printing Process

Printing on printable vinyl is a straightforward process that involves setting up your printer, adjusting the settings, and following the specific steps to ensure a successful print. Here’s a detailed guide to help you through the printing process:

Printer Setup

Begin by setting up your printer according to the manufacturer’s instructions. Ensure that the printer is connected to your computer and has the appropriate drivers installed. Load the printable vinyl into the printer’s paper tray, making sure it is facing the correct way. The printable side of the vinyl should be facing up towards the print head.

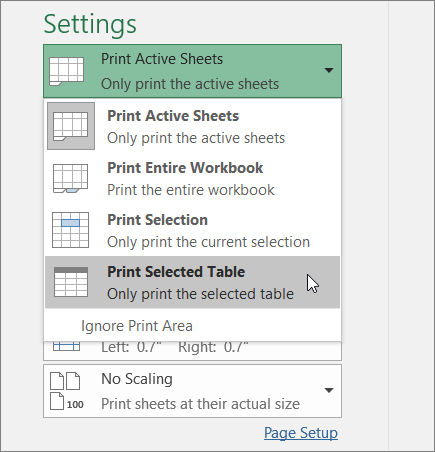

Printer Settings

Once the printer is set up, adjust the print settings to optimize the print quality. Select the highest quality print setting available on your printer. Choose the appropriate paper type, which should be “Printable Vinyl” or “Glossy Paper” depending on the type of vinyl you are using. Additionally, set the print mode to “Borderless” to ensure the ink covers the entire surface of the vinyl.

Finishing and Application

Once your vinyl is printed, you need to finish it and apply it to the surface you want to decorate.

To finish the vinyl, you can use a heat gun or a hair dryer to seal the ink and protect it from scratches and fading. You can also laminate the vinyl with a clear film to give it a glossy or matte finish and make it more durable.

Applying the Vinyl

To apply the vinyl, you need to clean the surface you want to decorate and make sure it is dry and free of dust and grease. Then, peel off the backing of the vinyl and apply it to the surface, smoothing it out with a squeegee or a credit card to remove any air bubbles.

You can use vinyl to decorate a variety of surfaces, including walls, furniture, cars, and windows. It is a versatile material that can be used to create a variety of looks, from simple and elegant to bold and colorful.

Troubleshooting

When printing on printable vinyl, it’s not all plain sailing, bruv. There can be a fair few snags that can get in the way of your vinyl vision.

But don’t fret, fam. We’ve got your back. Here’s the lowdown on some of the most common problems you might face and how to sort them out like a pro:

Printing too light or too dark

- Check your printer settings, blud. Make sure the print quality is set to ‘high’ or ‘best’.

- If that don’t work, try adjusting the colour balance in your design software.

- Still not right? Your printer might need a bit of TLC. Give it a clean and check the ink levels.

Ink smudging

- Let your ink dry properly before you touch it, innit. Give it a good 24 hours.

- If you’re in a rush, use a hairdryer on a low setting to speed things up.

- Make sure you’re using the right ink for your printer. Some inks are designed to dry faster than others.

Vinyl peeling off

- Clean the surface you’re sticking the vinyl to with rubbing alcohol. This will remove any dirt or grease that could stop the vinyl from sticking.

- Use a squeegee to apply the vinyl firmly. This will help to remove any air bubbles and ensure a good bond.

- If the vinyl is still peeling off, you might need to use a stronger adhesive.

Advanced Techniques

Yo, check it, vinyl printing ain’t just for beginners. If you’re keen on taking your game to the next level, listen up ’cause we’re gonna drop some knowledge on advanced techniques that’ll make your prints look like a pro’s. These tricks will elevate your designs, giving them that extra edge that’ll make ’em stand out from the crowd.

From layering colors to creating custom textures, we’ll show you how to unlock the full potential of printable vinyl. So, grab a brew, get comfy, and prepare to master the art of vinyl printing.

Layering Colors

Layering colors is like adding extra sauce to your pizza – it takes your prints to the next level of flavor. By printing multiple layers of vinyl, you can create depth, dimension, and gradients that’ll make your designs pop.

For instance, let’s say you’re making a vinyl decal for your ride. Instead of printing a flat blue design, try layering different shades of blue to create a cool ombre effect. Or, add a touch of white to your base color to give it a subtle shimmer.

Creating Custom Textures

Vinyl printing ain’t just about flat colors, fam. You can also create custom textures that’ll add a unique touch to your prints. By using different printing techniques and materials, you can mimic the look of wood, metal, or even leather.

For example, to create a wood grain texture, print a base layer of brown vinyl and then use a sponge or brush to apply a darker brown paint over it. The uneven application will give your print the appearance of real wood.

Applications

Printable vinyl has a wide range of applications, making it a versatile material for various projects.

Printable vinyl is commonly used for creating custom decals, stickers, and labels. It’s also popular for producing banners, signs, and displays. The material’s durability makes it suitable for outdoor use, such as on vehicles, storefronts, and construction sites.

Custom Decals and Stickers

Printable vinyl is a great choice for creating custom decals and stickers. These can be used to personalize laptops, phone cases, water bottles, and other items. Printable vinyl is also used to create wall decals, which can add a unique touch to any room.

Banners, Signs, and Displays

Printable vinyl is an excellent material for producing banners, signs, and displays. It’s durable, weather-resistant, and can be printed with vibrant colors. Printable vinyl banners are commonly used for advertising, promotions, and events. Signs made from printable vinyl can be used for wayfinding, safety instructions, and product displays.

Outdoor Applications

Printable vinyl is suitable for outdoor use due to its durability and resistance to fading and water damage. It’s commonly used for creating vehicle wraps, which can transform the appearance of cars, trucks, and other vehicles. Printable vinyl is also used for outdoor signs, banners, and displays, making it a versatile material for outdoor advertising and branding.

FAQ Summary

What is the difference between printable vinyl and regular vinyl?

Printable vinyl is a type of vinyl that has a special coating that allows it to be printed on with inkjet or laser printers. Regular vinyl, on the other hand, is not coated and cannot be printed on.

What are the benefits of using printable vinyl?

Printable vinyl is a durable and versatile material that can be used for a wide range of applications. It is resistant to water, fading, and tearing, making it ideal for both indoor and outdoor use. Additionally, printable vinyl is easy to cut and apply, making it a great choice for DIY projects.

What are the most common applications for printable vinyl?

Printable vinyl can be used for a wide range of applications, including:

- Signage

- Banners

- Labels

- Stickers

- Decals

- Wall art

- Product packaging