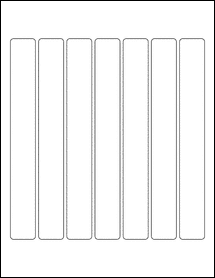

1 X 8 Printable Labels: A Comprehensive Guide for Customization and Efficiency

In the realm of organization and identification, 1 X 8 printable labels stand out as a versatile and practical solution. These labels offer a customizable canvas for conveying essential information, streamlining processes, and enhancing brand recognition. Whether you’re a professional seeking to optimize operations or an individual seeking to bring order to your personal space, understanding the nuances of 1 X 8 printable labels is key to maximizing their potential.

From understanding label dimensions and uses to exploring design and customization options, this guide delves into the intricacies of 1 X 8 printable labels. We’ll discuss the advantages of different materials and printing methods, provide tips for organizing and storing labels effectively, and examine industry-specific applications. Additionally, we’ll shed light on environmental considerations related to label production and disposal.

Understanding Label Dimensions and Uses

When it comes to printable labels, the size matters. 1″ x 8″ labels are a versatile and popular choice for a wide range of applications, from shipping and packaging to organizing and labeling. Understanding the dimensions and uses of these labels is key to choosing the right size for your specific needs.

The 1″ x 8″ label size is perfect for situations where you need a label that’s large enough to display important information, but not too big that it takes up too much space. These labels are commonly used for:

Shipping and Packaging

- Product labels

- Shipping labels

- Return address labels

Organization and Labeling

- File folders

- Storage bins

- Personal items

Design and Customization Options

Make your labels pop with a design that’s both eye-catching and informative. From fonts to colors and graphics, every element plays a role in creating a label that stands out.

Think about the message you want to convey and the audience you’re trying to reach. Your design should align with your brand identity and the overall tone of your message.

Font Selection

- Choose fonts that are easy to read, even from a distance.

- Consider the size and spacing of your text.

- Avoid using too many different fonts or styles.

Color Choices

- Use colors that contrast with the background.

- Consider the psychology of colors and how they can influence your message.

- Be consistent with your brand colors.

Graphics

- Add graphics to make your labels more visually appealing.

- Use high-quality images that are relevant to your message.

- Avoid cluttering your labels with too many graphics.

Material and Printing Considerations

Choosing the right material and printing method is essential for creating high-quality, durable labels. Let’s break down the pros and cons of different options:

Label Materials

- Paper: Cheap and easy to print on, but not very durable. Best for temporary or indoor use.

- Vinyl: Waterproof, tear-resistant, and versatile. Can be used for both indoor and outdoor applications.

- Polyester: The most durable material, resistant to chemicals, abrasion, and UV rays. Ideal for harsh environments or long-term use.

Printing Methods

- Inkjet: Affordable and easy to use, but prints can be smudged or faded over time.

- Laser: Produces crisp, permanent prints, but requires specialized equipment and can be more expensive.

Consider the intended use and durability requirements of your labels when selecting the material and printing method.

Organization and Storage

Keeping your labels organized and stored properly is essential to ensure they remain in good condition and are easy to find when needed.

To organize your label content, consider using HTML table tags to create logical sections or columns. This will make it easier to scan and locate specific information on each label.

Storing Printed Labels

Once your labels are printed, store them in a cool, dry place away from direct sunlight to prevent fading or damage. You can use a label organizer or binder to keep them organized and protected.

Distribution and Application

Once labels are created, distributing and applying them correctly is crucial for their intended use. Different surfaces require specific approaches to ensure optimal adhesion and visibility.

For smooth surfaces like glass, plastic, or metal, labels can be directly applied by peeling off the backing and pressing them firmly onto the surface. Ensure the surface is clean and dry for proper adhesion.

Textured Surfaces

For textured surfaces like wood, fabric, or cardboard, additional preparation may be necessary. Sanding or roughening the surface can create a better bond for the label. Alternatively, using a stronger adhesive or applying a primer can enhance adhesion.

Industry-Specific Applications

1″ x 8″ labels are versatile tools used across various industries, each with unique requirements and benefits. In retail, they serve as price tags, shelf labels, and promotional displays. Healthcare facilities utilize them for patient identification, medication labeling, and equipment tracking. Manufacturing industries employ them for inventory management, product identification, and quality control. Logistics and shipping companies leverage these labels for package tracking, shipping labels, and customs declarations.

Retail

- Price Tags: Clearly display product prices for easy customer identification.

- Shelf Labels: Organize and categorize products, making it easier for customers to find what they need.

- Promotional Displays: Highlight special offers, discounts, and new products to attract attention and drive sales.

Healthcare

- Patient Identification: Provide essential information about patients, such as name, medical history, and allergies.

- Medication Labeling: Clearly label medications with dosage instructions, expiration dates, and patient information.

- Equipment Tracking: Keep track of medical equipment, ensuring its availability and proper maintenance.

Manufacturing

- Inventory Management: Track and manage inventory levels, ensuring efficient stock control.

- Product Identification: Identify products clearly with product codes, descriptions, and specifications.

- Quality Control: Label products with inspection dates, batch numbers, and other quality control information.

Logistics and Shipping

- Package Tracking: Track packages throughout the shipping process using unique tracking numbers.

- Shipping Labels: Provide essential information for shipping, including recipient address, sender details, and handling instructions.

- Customs Declarations: Comply with customs regulations by providing necessary information on shipments crossing borders.

Environmental Considerations

In today’s eco-conscious world, it’s crucial to consider the environmental impact of our actions, including the production and disposal of labels.

Sustainable practices in label production include using biodegradable and recyclable materials, reducing waste, and employing eco-friendly printing techniques.

Biodegradable and Recyclable Label Materials

Biodegradable labels are made from materials that can naturally decompose, such as plant-based cellulose or starch. These labels are an excellent option for products with a short shelf life or those intended for composting.

Recyclable labels are made from materials that can be reprocessed into new products. This reduces the amount of waste sent to landfills and conserves natural resources.

FAQ Corner

What are the common uses for 1 X 8 printable labels?

1 X 8 printable labels find applications in a wide range of industries and personal settings. They are commonly used for product labeling, shipping and logistics, asset tracking, inventory management, and organization of files, folders, and storage containers.

What factors should be considered when choosing the material for 1 X 8 printable labels?

The choice of material for 1 X 8 printable labels depends on the intended use and environment. Paper labels are cost-effective and suitable for indoor use, while vinyl labels offer durability and resistance to moisture and chemicals. Polyester labels provide high durability and resistance to extreme temperatures, making them ideal for outdoor applications.

What is the best printing method for 1 X 8 printable labels?

The optimal printing method for 1 X 8 printable labels depends on the material and desired print quality. Inkjet printing is suitable for small-scale printing on paper labels, while laser printing offers higher resolution and is ideal for printing on vinyl and polyester labels.

How can I organize the content on 1 X 8 printable labels?

To organize the content on 1 X 8 printable labels effectively, you can use HTML table tags to create logical sections or columns. This allows you to structure the information clearly and enhance readability.

What are some tips for storing printed 1 X 8 printable labels?

To ensure the longevity of printed 1 X 8 printable labels, store them in a cool, dry place away from direct sunlight. Use airtight containers or resealable bags to protect them from moisture and dust.